My Store

Helical Gear Design Service

Helical Gear Design Service

Measurements

Couldn't load pickup availability

This is a fixed-fee consulting package (NRE) for the complete design of a custom helical gear set.

Deliverables:

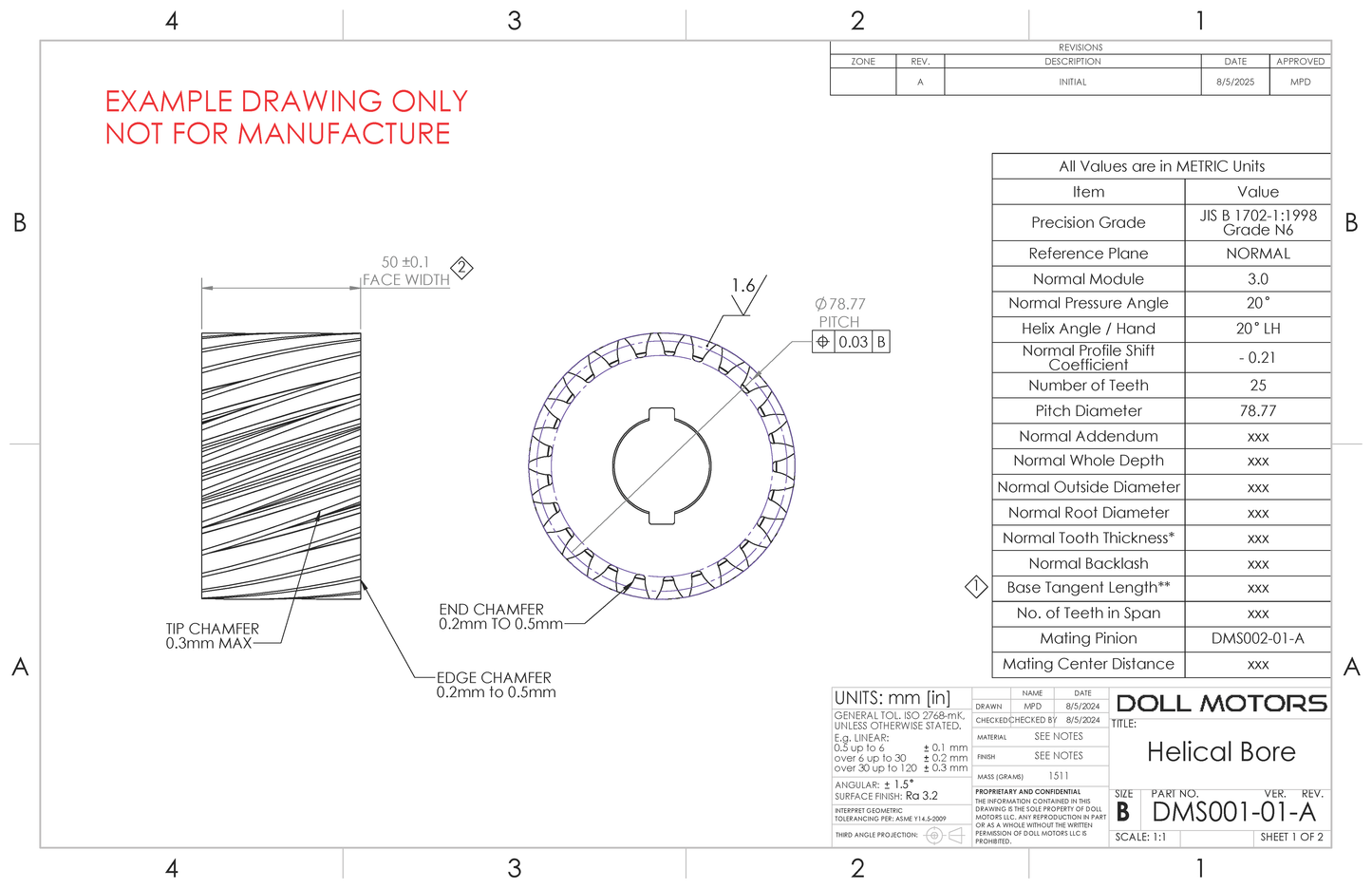

- 2D drawing file of pinion (driver) and gear (driven) in PDF format

- 3D CAD file of pinion and gear in STEP format*

- Ratings, gear forces, and lubrication report

- Review meeting (1 hour) to consult and finalize dimensions

*Teeth shown in the 3D CAD file are for reference only and are not accurate to final manufacturing geometry due to the complexity of gear geometry.

Design Process and Standards:

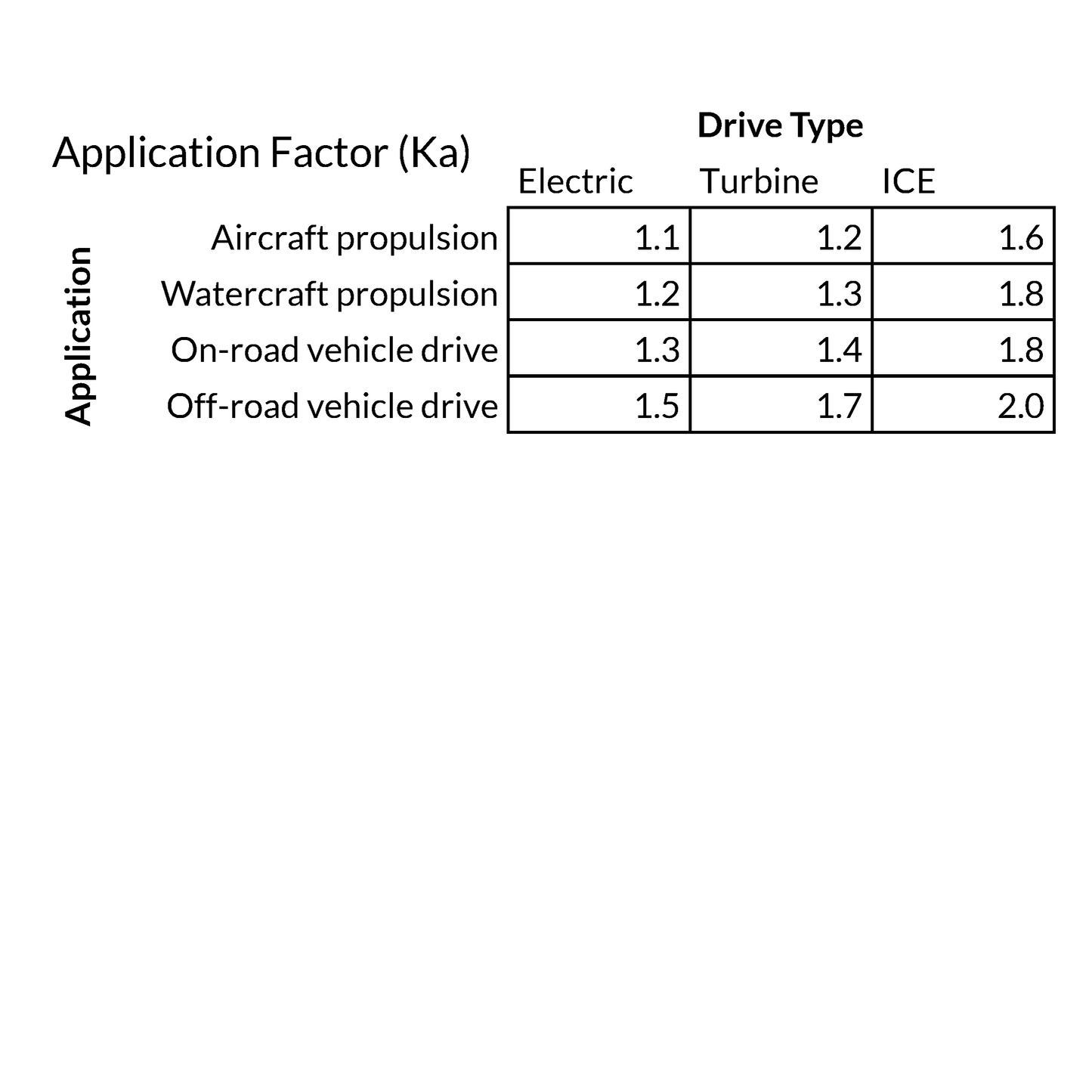

We apply established gear design practices to ensure optimal performance, reliability, and manufacturability. Based on your exact requirements, we will adjust module, helix angle, number of teeth, backlash, profile modification, crowning, contact ratio, and other critical parameters to achieve the smallest possible gear, with maximum performance.

All of our helical gears include the following standard characteristics:

- Power gears optimized for high-efficiency and low-noise

- Speed-reducing (torque-increasing)

- Involute tooth form

- Induction hardened and ground Cr-Mo Steel

- Parallel Axis

- 20° Pressure Angle

- Precision Grade N6 (JIS B 1702-1:1998)

Our designs achieve smaller outer diameters without compromising torque capacity by extending face width and applying optimized crowning, an approach proven in high-performance gearboxes. You will not find this in your typical stock gear offerings.

Note: all of our gear sets are speed-reducing (torque-increasing). The "pinion" is the smaller driver gear, while the "gear" is the larger driven gear.

Interface Selection:

Choose an interface type for both pinion and gear. Interfaces are designed for a minimum shaft yield strength of 800 MPa (through-hardened Cr-Mo steel).

In order of strength:

Integrated shaft (strongest) > Spline > Dual keyway > Single keyway (weakest)

When to select “Integrated shaft” for the pinion:

Integrated shafts are ideal for maximum performance pinions. Since we optimize the pinion to have the fewest number of teeth, and therefore smallest diameter, there is little room for a bore with a keyway. This can result in an undersized shaft. By integrating the shaft and pinion into a single part, the shaft can be larger and achieve a torque capacity equivalent to, or greater than, the pinion itself. If integrated shaft is not possible, spline is the next best option.

Spline Manufacturing Cost:

Splines will directly increase the manufacturing cost of the gear due to tooling, or EDM wire cutting. All other interface options are typically lower cost.